Introduction

In today’s competitive market, maintaining high packaging standards is essential for businesses across industries like food, beverage, cosmetics, and pharmaceuticals. One small but critical component of packaging quality is the tightness of bottle caps, as improper sealing can lead to leaks, spoilage, or product contamination. This is where Bottle Cap Torque Tester pricecome into play. These tools measure the force required to twist open or close a cap, ensuring that every bottle meets quality specifications. In this blog post, we’ll cover what bottle cap torque testers do, why they matter, and how to choose the right one for your business.

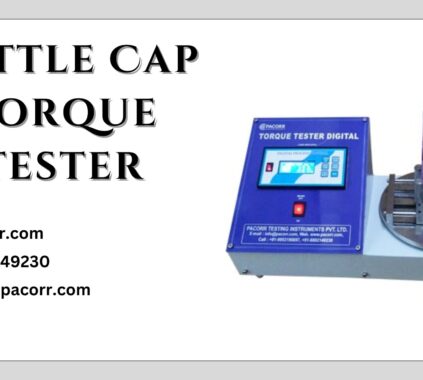

What Exactly is a Bottle Cap Torque Tester?

Do you want to visit Haridwar? travel agents in Haridwar is the right place to plan your tour. You can book your tour from here.

A bottle cap torque tester is a device that measures the amount of rotational force, or torque, needed to open or close a bottle cap. The correct torque level ensures that the cap is secure enough to prevent leaks but not so tight that it’s difficult for consumers to open.

These testers work with a variety of Bottle Cap Torque Machine Pricematerials, like plastic, glass, and metal, and different cap types, from twist-off lids to child-resistant closures. Torque testers are widely used across various sectors, including pharmaceuticals, food and beverage, cosmetics, and chemicals, making them invaluable for maintaining quality and safety.

Key Benefits of Using a Bottle Cap Torque Tester

Do you want to visit char dham? char dham tour operator is the right place to plan you Char Dham tour. You can book you tour from here.

- Ensuring Product Safety and Quality

- By ensuring that caps are sealed with the right amount of torque, testers help prevent leaks, contamination, and spoilage, all of which can compromise product safety and quality. Many industries have strict regulations on packaging standards, and torque testers help meet these compliance requirements.

- Protecting Brand Reputation

- A secure, easy-to-open cap contributes to a positive user experience. Leaks or caps that are too tight can lead to frustration, damaging the brand’s reputation. Torque testers ensure that every product is safely and conveniently packaged for consumers.

- Reducing Production Waste and Cost

- Consistent Bottle Cap Torque Testerlowers the likelihood of packaging errors that could lead to product recalls, returns, or waste. By catching issues early, businesses save on costs associated with repackaging or product loss.

- Streamlining Quality Control in Production

- Torque testers allow manufacturers to catch issues early on, reducing downtime and ensuring a smoother, more efficient production process. This consistency helps meet high production standards and minimizes the risk of bottlenecking in quality control.

- Improving Customer Satisfaction

- Bottle caps that are neither too loose nor too tight make for a better consumer experience. Torque testing ensures that caps are easy to open while still being secure, enhancing overall customer satisfaction and loyalty.

How Does a Bottle Cap Torque Tester Work?

A bottle cap torque tester uses a simple yet effective process to measure the force applied to a cap. Here’s an outline of the basic steps:

- Placing the Bottle: The bottle is positioned in the tester’s holding device, which secures it in place.

- Applying Torque: The tester applies rotational force to the cap, recording the torque level required to open or close it.

- Recording Results: The tester logs the torque measurement, allowing operators to assess whether it meets pre-set standards. Digital testers often display readings and can store data for future analysis.

- Making Adjustments: If the torque falls outside acceptable ranges, production equipment can be adjusted accordingly, ensuring that each cap meets quality specifications.

Some advanced Bottle Cap Torque Testingcome with digital displays, automated settings, and data storage, making them ideal for high-output facilities where precision and efficiency are paramount.

Choosing the Right Bottle Cap Torque Tester for Your Business

When it comes to selecting a bottle cap torque tester, there are several important factors to consider:

- Compatibility with Bottles and Caps: Ensure the tester is compatible with the types and sizes of bottles and caps you’re using, as certain models may be tailored to specific materials or cap types.

- Required Accuracy: Some industries, like pharmaceuticals, require highly precise torque measurements. If your industry has specific standards, look for a model that provides the level of accuracy you need.

- User-Friendly Design: Torque testers with digital displays and intuitive controls are easier for staff to operate. Automated or digital options can streamline the process, particularly in high-production settings.

- Durability and Maintenance: Select a model designed for durability, especially if it will be used frequently. Durable models with accessible maintenance options ensure consistency and reduce downtime.

- Data Storage and Reporting Features: If your business requires detailed records for quality control, look for a torque tester with data storage or connectivity features. This can simplify tracking, compliance, and data analysis over time.

Why Pacorr.com is Your Trusted Source for Bottle Cap Torque Testers

Do you want to visit Indiar? tour operator in India is the right place to plan your tour. You can book your tour from here.

Pacorr.com offers a wide selection of high-quality Bottle Cap Torque Tester pricedesigned for various industries. With Pacorr’s testers, you’ll get accurate measurements that meet quality standards and help you maintain your product’s integrity. Our testers are built to be durable and user-friendly, making them an ideal addition to any quality control process.

Our team at Pacorr is dedicated to helping you find the right solution for your packaging needs, no matter your industry. From food and beverages to cosmetics and pharmaceuticals, our torque testers support your commitment to quality and customer satisfaction.

Conclusion

In the world of packaging, ensuring that bottle caps are secure yet easy to open is key to maintaining product quality, safety, and consumer satisfaction. Bottle cap torque testers are invaluable for achieving this balance, giving businesses the peace of mind that their products are securely sealed and ready for the market. By choosing the right Bottle Cap Torque Machine Price, companies can streamline their quality control processes and protect both their brand reputation and customer trust. Visit Pacorr.com to explore a range of reliable torque testers and take a step toward enhanced packaging quality control.

Bottle Cap Torque Tester FAQ

What is a Bottle Cap Torque Tester?

A device that measures the rotational force (torque) needed to open or close Bottle Cap Torque Tester Manufacturers, ensuring secure sealing without being too tight for consumers.

Why is Cap Torque Important?

Proper torque prevents leaks, contamination, and ensures caps are consumer-friendly, meeting safety and quality standards.

Which Industries Use Torque Testers?

Common in pharmaceuticals, food and beverage, cosmetics, and household chemicals.

How Does a Torque Tester Work?

It grips the bottle and applies rotational force to measure the required torque, helping verify cap tightness.

What Should I Consider When Choosing One?

Look for compatibility with cap types, required accuracy, ease of use, durability, and data logging features.

Can One Tester Handle Different Cap Types?

Yes, many are designed for various caps, including twist-off and child-resistant caps.

Where Can I Buy a Reliable Torque Tester?

Visit Pacorr.com for a variety of durable, accurate testers tailored to industry needs.