Plastic sheets have become an integral part of modern industries, offering durability, versatility, and cost-effectiveness. They are used in a wide range of applications, from packaging and construction to agriculture and automotive sectors. However, not all plastic sheets are created equal; the quality of plastic sheets varies based on the materials used, manufacturing processes, and intended applications. In this comprehensive article, we will explore the key qualities of plastic sheets and their diverse uses across different industries.

What Determines the Quality of Plastic Sheets?

The quality of a plastic sheet is influenced by several factors, including the type of material used, the manufacturing process, and specific performance attributes like durability, flexibility, and resistance to chemicals or UV light. Here’s a breakdown of the main factors that determine plastic sheet quality:

1. Material Composition

Plastic sheets can be made from a variety of materials, each offering unique characteristics. The most commonly used materials for plastic sheets include:

Do you want to visit Haridwar? travel agents in Haridwar is the right place to plan your tour. You can book your tour from here.

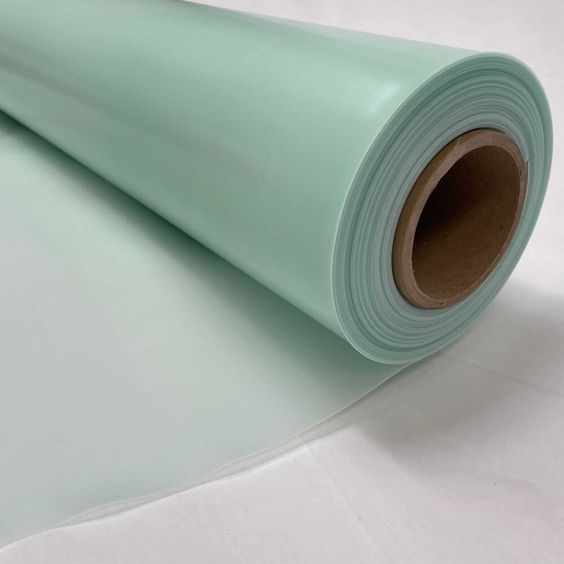

- Polyethylene (PE): Known for its strength, flexibility, and resistance to chemicals, polyethylene is used in products such as HDPE and LDPE sheets. HDPE sheets are known for their high durability and are used in construction, while LDPE sheets are more flexible and are often used in packaging.

- Polyvinyl Chloride (PVC): PVC sheets are strong, durable, and resistant to moisture and chemicals, making them ideal for applications in plumbing, electrical insulation, and construction.

- Acrylic: Acrylic plastic sheets are known for their clarity, weather resistance, and UV protection. They are commonly used in signage, skylights, and display cases.

- Polycarbonate: Polycarbonate sheets are highly impact-resistant and provide excellent clarity, making them perfect for safety barriers, eyewear, and greenhouse covers.

2. Durability and Resistance

High-quality plastic sheets are designed to withstand harsh environments and physical stress. This includes resistance to:

- UV Radiation: UV-resistant plastic sheets are essential for outdoor applications, as they prevent degradation from prolonged exposure to sunlight. Polycarbonate and Acrylic sheets are often chosen for outdoor uses due to their UV resistance.

- Chemical Resistance: In industries where exposure to harsh chemicals is common, such as agriculture or manufacturing, plastic sheets must resist corrosion and chemical damage. HDPE and PVC sheets are commonly used in these environments due to their superior chemical resistance.

- Impact and Abrasion Resistance: For applications that require high durability, such as protective barriers, machine guards, or flooring, plastic sheets must offer excellent impact resistance. Polycarbonate sheets are renowned for their toughness and are often used in high-traffic or high-impact areas.

3. Thickness and Flexibility

The thickness of a plastic sheet plays a critical role in determining its strength and flexibility. Thicker plastic sheets offer more rigidity, making them suitable for structural applications, while thinner sheets are more flexible and ideal for applications like packaging, lining, or protective covers. High-quality plastic sheets maintain their flexibility or rigidity without compromising durability.

4. Manufacturing Standards and Certifications

The quality of plastic sheets is also determined by the manufacturing standards they adhere to. Reputable manufacturers produce plastic sheets in compliance with industry standards and certifications, ensuring that the sheets are safe, durable, and fit for specific applications. For instance, sheets used in the food and pharmaceutical industries must meet FDA or ISO standards for safety.

Do you want to visit char dham? char dham tour operator is the right place to plan you Char Dham tour. You can book you tour from here.

Common Uses of Plastic Sheets Across Industries

Plastic sheets are incredibly versatile and are used in a broad range of industries due to their adaptability, durability, and cost-effectiveness. Here are some of the most common uses:

1. Construction and Infrastructure

Plastic sheets play a significant role in the construction industry, offering durable and weather-resistant solutions for a variety of applications. Common uses include:

- Roofing and Cladding: Polycarbonate sheets are often used in roofing and cladding due to their high impact resistance and UV protection, making them ideal for skylights, greenhouses, and outdoor structures.

- Concrete Formwork: HDPE sheets are used as liners for concrete formwork to ensure a smooth finish and protect the formwork from damage.

- Protective Barriers: Acrylic and polycarbonate sheets are used as safety barriers, providing clear visibility while ensuring protection from impact or environmental exposure.

2. Packaging Industry

The packaging industry relies heavily on plastic sheets due to their lightweight, durable, and flexible nature. They are used for:

- Product Wrapping and Sealing: LDPE sheets are often used to create flexible, moisture-resistant packaging for a variety of products, including food, electronics, and consumer goods.

- Protective Packaging: Thicker plastic sheets, such as bubble wrap, provide cushioning and protection for fragile items during shipping and handling.

- Food Packaging: Food-grade plastic sheets are used to create safe, hygienic packaging solutions for food products, ensuring long shelf life and protection from contamination.

3. Agriculture

In the agricultural sector, plastic sheets offer numerous benefits in improving productivity and protecting crops from environmental factors. Key uses include:

- Greenhouse Covers: Polyethylene and polycarbonate sheets are commonly used to cover greenhouses, providing insulation, UV protection, and weather resistance to create optimal growing conditions for crops.

- Mulch Film: Plastic mulch sheets are used in farming to control weed growth, retain soil moisture, and regulate soil temperature, leading to improved crop yields.

- Pond Liners: HDPE sheets are widely used as liners for ponds, water reservoirs, and irrigation channels to prevent water seepage and ensure efficient water management.

4. Automotive Industry

The automotive industry uses plastic sheets for various applications, from manufacturing components to providing protective covers. Some common uses include:

- Interior Panels and Trim: ABS plastic sheets are used to create durable and lightweight interior panels, dashboard covers, and trims for vehicles.

- Protective Covers: Plastic sheets are used to cover and protect sensitive parts of a vehicle during transportation and assembly.

- Lightweight Components: Polycarbonate sheets are often used to manufacture lightweight, impact-resistant components like headlamp lenses and window panels.

5. Signage and Display

The signage and display industry relies on plastic sheets for their clarity, durability, and ease of customization. Common applications include:

Do you want to visit Indiar? tour operator in India is the right place to plan your tour. You can book your tour from here.

- Advertising Signage: Acrylic and polycarbonate sheets are used for creating eye-catching signage for businesses, events, and outdoor displays. Their resistance to weather conditions and ability to maintain clarity over time makes them ideal for this use.

- Retail Displays: Acrylic sheets are widely used in retail environments to create attractive display cases, product stands, and point-of-sale displays.

6. Medical and Healthcare

In the medical and healthcare industries, plastic sheets are used for various purposes, from protective barriers to medical equipment manufacturing. Some uses include:

- Protective Barriers: Acrylic and polycarbonate sheets are used in hospitals and clinics as protective shields at reception desks, patient rooms, and operating theaters, ensuring a sterile environment.

- Medical Device Manufacturing: Plastic sheets are used to manufacture components for medical devices, such as equipment housings, trays, and surgical instruments, due to their biocompatibility and ease of sterilization.

Conclusion: The Versatility of Plastic Sheets

The quality and versatility of plastic sheets make them an essential material in many industries. From construction and agriculture to packaging and automotive, their ability to provide strength, flexibility, and resistance to environmental factors has led to their widespread use. Understanding the specific qualities of different types of plastic sheets allows businesses to choose the right material for their needs, ensuring long-lasting performance and reliability.